Software Engineer

JOB SUMMARY

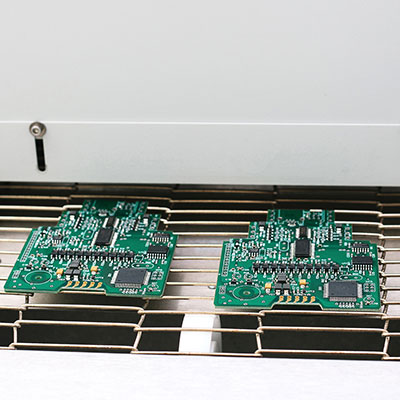

Simplimatic, A Signode Brand is currently seeking a Software Engineer to perform software design, developmental, and testing duties for electro-mechanical automation devices and machines for the electronics, optical, personal care and pharmaceutical industries.

The successful applicant will need to be able to apply principles and techniques of software engineering to accomplish the following goals:

- Develop new product concepts and designs

- Prototype and evaluate new product ideas

- Investigate new software technologies and tools

- Support products and interact with customers through the beta period, including training

- Help Customer Support with technical content for product manuals

Duties & Responsibilities

- Full lifecycle application development

- Designing, coding and debugging applications in C# and C++ using Microsoft Visual Studio

- Software modeling and simulation

- Front end graphical user interface design

- Software testing and quality assurance

- Performance tuning and improvement

- Support, maintain and document software functionality

- Integrate software with existing systems (working with controls engineers and communicating with many different types of industrial devices)

- Evaluate and identify new technologies for implementation

- Maintain standards compliance

- Other duties as needed or assigned

Job Qualifications:

- Minimum BS degree in Computer Science or minimum of 5 years experience in C# or C++ development for industrial automation

- Experience with BOTH C# and C++ is a plus

- Experience with machine vision is a plus

- Experience with microcontrollers (such as Arduinos) is a plus

- A deep understanding of advanced mathematics such as Calculus and Linear Algebra is a plus

Personal Characteristics:

- Results oriented with a “can-do” attitude

- Strong analytical, numerical, and reasoning abilities

- Excellent problem-solving skills and ability to resolve highly complex problems in a timely manner

- Excellent time management, organizational, and prioritization skills, to successfully complete a wide variety of complex job duties and responsibilities in a timely manner

- Works effectively in multi-disciplined project teams