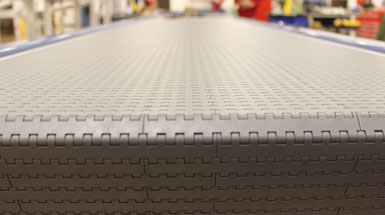

Sanitary Mat Top Conveyor

The Simplimatic® sanitary stainless steel mat-top conveyor allows for easy clean-in-place (CIP) maintenance and servicing. Conveyor segments are joined using stainless steel spacers rather than the traditional butt seams while the system’s bearings and motor mounts are set off the conveyor frame to allow for cleaning brush access.

Simplimatic’s Mat Top conveyor systems are a collection of high-quality, conveyor components designed to reliably transport bulk goods between processes during bottling, packaging, assembly, and manufacturing. Utilizing multiple frame types and chain styles, Simplimatic’s Mat Top conveyor provides customers with the ability to select a bulk-material handling system that is perfectly engineered to solve a project’s mass conveying needs.

Simplimatic conveyor systems are designed to provide customers with an easy-to-integrate Mat Top conveyor solution. Simplimatic’s steel and aluminum versions of Mat Top conveyors feature:

- Reliability – American-made design, assembly, and support to ensure long-lasting equipment performance

- Standardized – beams and brackets allow for ceiling-hung or floor-mounted installation

- Affordability – Low-cost, high-performance modular product guide system for line flexibility

- Multiple chain varieties – Simplimatic Mat Top Conveyor Systems are offered with a solid top, high friction, perforated top, and low backpressure mat top chain

- Heavy-duty drive and idle assemblies – Simplimatic pairs the mat top conveyor systems with drive options including Direct Drive, Transmission Drive, Power-transfer Drive, and Dynamic Curve Drive

Simplimatic has built the framework necessary to ensure lifetime spares, service, and support are available for all Simplimatic products installed around the globe. Contact Simplimatic today for more information on Simplimatic’s Mat Top Conveyor systems or to request a quote.

SKU: Simplimatic Sanitary Mat Top Conveyor

- Available in stainless steel, carbon steel, or modular aluminum construction to provide a conveying solution for nearly any bulk-handling application

- Customizable length to suit any factory environment

- Multiple drive options to suit a variety of loads and environments

- Several chain options available including solid top, high friction, low backpressure, and perforated top

- Compatible with Intralox®, Rexnord®, Habasit®, and Uni® Mat Top chains

- Simplimatic’s Mat Top conveyor is available in 6’’, 12’’, 18’’, 24’’, 30’’, and other custom belt widths

- Without moving the plastic mat-top chain, operators can easily clean the carry way, return way chain, wear strip surfaces, bearings, and motor mounts

- Horizontal cross braces on the tubular steel legs are welded to the vertical support legs with the flat surfaces at 45 off vertical to prevent water from accumulating on the surface

- Backed by worldwide service and support from Simplimatic Automation

- Designed and built in the USA