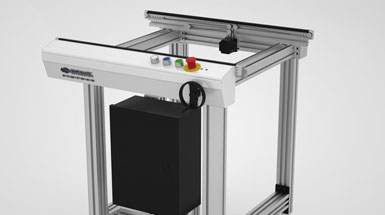

Cimtrak® JEDEC Tray Flipper

Simplimatic’s Cimtrak JEDEC Tray Flipper is a fully automated solution for flipping a stack of JEDEC trays on the long axis of the tray. The unit helps maintain employee ergonomics through the minimizing of manual tray handling of standard 12.7’’ (322.6 mm) x 5.35’’ (136 mm) trays.

The system flips trays before or after bottom-side/dead-bug processing and is controlled by two switches on the machine’s sides to ensure operator safety. The system also features a light tower and alarms to signal any errors. JEDEC trays are secured from the side, top, and bottom to prevent slipping or falling from the slot. The machine can also handle short or tall stacks with no additional operator setup or intervention.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

Each electrostatic dissipative Cimtrak® product features:

- Solid conveyor belt construction – Non-spliced, fiberglass-reinforced transmission belts for superior strength

- Reliable DC stepper motors – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Premium rail design – Cimtrak conveyor features zero gaps between belt and edges to eliminate jams

- Adjustable in-feed tips – Can be lengthened by up to 4’’ for easy install

- Extruded aluminum framework – Provides light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

Contact a member of the Simplimatic sales team for more information or to request a quote for Cimtrak Flat Belt Conveyor.

SKU: Cimtrak® JEDEC Tray Flipper – Model 3262

Cimtrak JEDEC Tray Flippers serve as a custom, fully automated JEDEC handling solution | Touchscreen interface with full machine diagnostics | Typical applications include: Flipping both short and tall stacks of JEDEC trays | Electricity required: 110 V AC, 5 amps, 50/60 Hz | Air (optional): 80 PSI, 2 CFM.

- Improves ergonomics and reduces operator fatigue

- Precision-cut, proprietary aluminum extrusion and steel frame

- Tooled entry and shutdown required for electrical panel

- Dead man’s switches on machine’s sides to ensure operator safety

- DC stepper motors for adjustable velocity, torque, and acceleration

- Rugged aluminum and steel sandwich construction

- Other customer-specified voltages available

- Optional SCADA software for smart industry 4.0 communication

- JEDEC trays secured from the side, top, and bottom to prevent product falling or slipping

- Backed by worldwide service and support from Simplimatic Automation

- Design and built in the USA