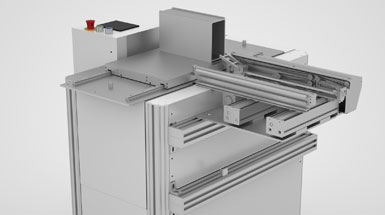

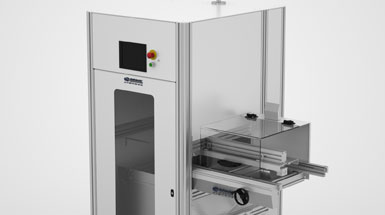

Cimtrak® FIFO/LIFO Buffer (Servo Motor)

Cimtrak First-In, First-Out (FIFO), and Last-In, Last-Out (LIFO) Buffers are designed to help balance the flow of your production line by temporarily storing work in progress. These buffers are available in a 30 slot capacity, each able to hold products from 2” x 3” to 18” x 22” in size. The carriage is designed to take very heavy loads, while the zero-clearance conveyor guides can accommodate very thin products.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

Each electrostatic dissipative Cimtrak product features:

- Solid conveyor belt construction – Non-spliced, fiberglass-reinforced transmission belts for superior strength

- Reliable DC stepper motors – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Premium rail design – Cimtrak® conveyor features zero gaps between belt and edges to eliminate jams

- Adjustable in-feed tips – Can be lengthened by up to 4’’ for easy install

- Extruded aluminum framework – Provides light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

First-In, First-Out or Last-In, Last-Out Operation | Closed-loop servo positioning | High-speed DC stepper motor conveyor | Individual belt sections | Patented conveyor drive assembly | Hand crank width adjust | Typical applications include: Inline buffering before bottlenecks or inconsistent processes, such as manual assembly areas; evacuating reflow ovens if post-reflow processes slow or stop; same side in/out buffering | Electricity required: 110 V AC, 5 amps.

- Power width control (PWC)

- Tooled width adjust – requires tools to adjust

- Large frame version – increases footprint and handles 18” x 24” boards

- Cooling fans

- Dual lane

- Uninterruptible power supply (UPS)

- 10-, 20-, 30-, and 40- slot capacities

- Standard upline inhibit software allows the FIFO/LIFO Buffer to regulate transfers at other machines to balance the line and ensure the buffer is never filled

- Other customer-specified voltages available

- Patented floating conveyor drive assembly is reliable and easy to set up

- Teach positions, carriage pitch, inhibit values, board capacity, and “first slot” variables are easily programmed at the user interface

- Closed-loop feedback in the carriage positioning system ensure precise and repeatable transfers

- Pass-through, stop input, and stop output modes

- Backed by worldwide service and support from Simplimatic Automation

- Design and built in the USA