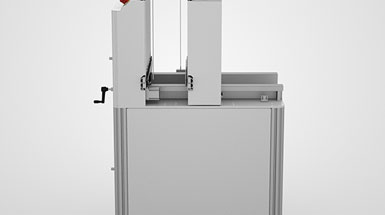

Cimtrak® Bare Board Vacuum Loader

Cimtrak Bare Board Vacuum Loaders are designed for introducing unpopulated boards into a high-volume, low-mix environment. Its high-capacity storage bin accommodates a 20″ (50.8 cm) stack of printed circuit boards (PCBs) and allows the unit to run unattended for long periods of time. The pneumatic lift design works well with either large board or extremely thin board loading applications. Each unit can automatically halt its operation to operate in pass-through mode. Average board loading cycle time with this system is seven seconds.

Each unit is capable of independent operation utilizing an on-board Allen Bradley® PLC, but the system is designed to be linked with other up-line or down-line PCB handling systems using SMEMA communications.

Simplimatic’s electronics design philosophies have been highly regarded by the electronics industry since 1988 and are known to have an average service life of more than 15 years.

Each electrostatic dissipative Cimtrak product features:

- Solid conveyor belt construction – Non-spliced, fiberglass-reinforced transmission belts for superior strength

- Reliable DC stepper motors – Virtually service free and allows for precise adjustments to velocity, torque, and acceleration

- Premium rail design – Cimtrak conveyor features zero gaps between belt and edges to eliminate jams

- Adjustable in-feed tips – Can be lengthened by up to 4’’ for easy install

- Extruded aluminum framework – Provides light and strong chassis

- Industry 4.0 communication – Available with several PLC options and can be configured for smart industry 4.0 communication

High-speed DC stepper motor conveyor | Pass-through mode | Hand crank width adjust | Expandable and easy-to-adjust vacuum cup array | Holds 20” stacks of PCBs measuring up to 18” x 20” | Seven-second cycle time | Electricity required: 110 V AC, 5 amps | Air required: OFA, 80 PSI, 3 CFM.

- Power width control

- Right-to-left transfer

- Auxillary vacuum cups – help lift larger boards

- Vacuum-selector switch-speeds changeover by allowing patterns of vacuum cups to be selected

- Tooled width adjust – requires tools to adjust

- Gantry system and conveyor rails are permanently calibrated, ensuring accurate board placement throughout the life of the machine

- Zero-clearance edge guides eliminate the danger of boards becoming jammed

- Step-through mode allows the user to pause at each step of the loading process to allow for efficient set up and changeover

- The vacuum cup array is adjustable without tools

- Additional vacuum cups can be added to speed changeover or increase the lift capacity, as required

- Other customer-specified voltages available

- Standard Allen-Bradley controller system can be expanded to include network capability

- Modular conveyor rails allow the length of the conveyor to be significantly increased or decreased at a minimal cost

- No driveshafts to align or guard

- Backed by worldwide service and support from Simplimatic Automation

- Design and built in the USA