Printed Circuit Board Laser Marker

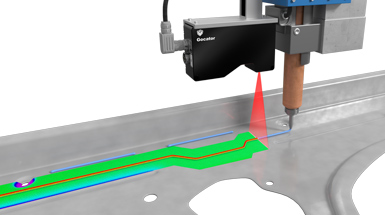

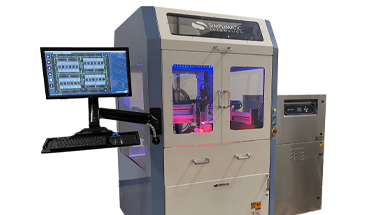

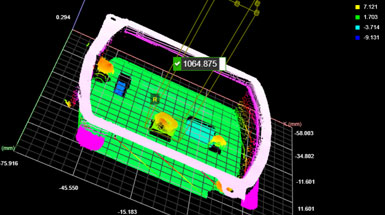

Robotic laser automation systems are fast, precise, and have pinpoint accuracy. Performing any laser function traditionally is obsolete. Robotic Laser solutions will improve your manufacturing throughput, your facility’s efficiency, processes, repeatability and let you have traceability over your products and steps in your manufacturing line. Today, lasers are less complex, more stable, and have improved software which makes Simplimatic’s Laser Marker platforms are designed with unparalleled flexibility in marking multiple surface types at different heights with a high degree of speed and precision. This system has fully integrated PC controls with a decoupled laser and scan head. Inherent to the system is a robust machine interface that works well in a lab or in production environments. The Simplimatic® Laser Marker has configurable head combinations and programmable marking head height capable of marking the top and bottom of boards simultaneously. The flexibility with beam conditioning in this system is perfect for companies that want to protect their investment for total cost of ownership. This is a customizable platform that can be designed to customer specifications.

- Custom filtration system – clean air, all in one system

- Small footprint – 0.8 m x 1.2 m (depth) or 2.6 ft x 3.9 ft

- Modular design

- Decoupled laser / scan head

- Configurable laser / head combinations

- Capable of marking top and bottom simultaneously

- Customizable platform for customer specification

- Programmable marking head height

- Mark inspection with dual fixed cameras

- Customizable mark library

- Touch screen display

- High-speed servo motor conveyor

- 30-watt CO2 laser – air cooled laser, decoupled laser/scan head combinations

- Windows 10 operating system

- Full-size touchscreen with keyboard

- SMEMA compliant

- Alpha-numeric, 1D and 2D code marking, human readable

- Multi-plane marking capability

- Lan compatible

- Single or dual laser scan heads

- Servo controlled laser focal distance

- PC controls

Footprint

3.9’ (1.2m) in length

2.6’ (.8m) in width

8.5′ (2.6m) in height

Board Handling Capability

Edge clearance: 3mm or 5mm (.11” or .19”)

PCB max length: 508mm (20”)

PCB max width: 457mm (3-18”)

PCB Thickness: up to 7mm (.27”)

Allowable warpage: 0.007”per in, 0.125 Max

Marking area: 300mm x 300mm (11.81”x11.81”)

Facility Requirements

Electricity: 200-240VAC, 30A